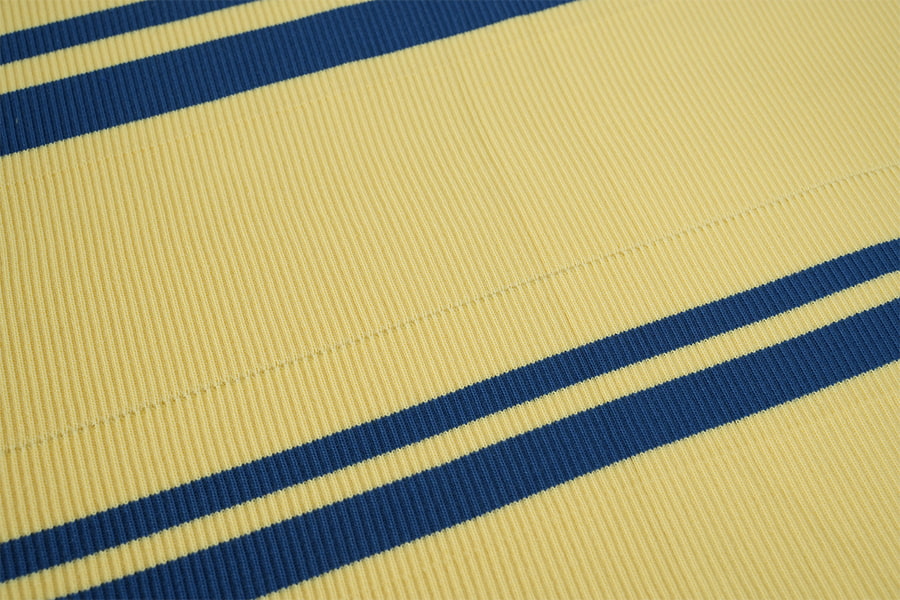

Horizontal rib is a kind of knitted fabric widely used in clothing and home decoration. Its unique structure, excellent elasticity and soft texture make it popular in the market. However, the dyeing process of horizontal rib is highly technical, and the choice of dyeing method is affected by many factors, which requires in-depth analysis and research.

Fabric characteristics analysis

Horizontal rib fabric is composed of knitted loops and has a unique coil structure and elasticity. This structural characteristic makes horizontal rib show high moisture absorption and easy coloring during the dyeing process, but it may also cause problems such as color flower and color difference. Therefore, these fabric characteristics must be fully considered when choosing a dyeing method.

Fiber composition: horizontal rib fabric can be made of natural fibers (such as cotton, wool) or synthetic fibers (such as polyester, nylon). Different fiber components have significant differences in the adsorption, permeability and color fixation of dyes. Natural fibers usually have a good affinity for dyes, but are prone to color flower phenomenon; while synthetic fibers may require higher temperature and pressure to achieve ideal dyeing effects.

Tissue structure: The tissue structure of horizontal rib directly affects the tightness and elasticity of its coils. Tight coil structures may make it difficult for dyes to penetrate, while loose coil structures may cause excessive dye penetration, which may lead to color flowers or color differences.

Elasticity: Horizontal ribbed fabrics have good elasticity, but if they are stretched or compressed during the dyeing process, they may cause the fabric to deform, affecting the final dyeing effect and fabric quality.

Requirements for dyeing effects

The different requirements of products for dyeing effects directly affect the choice of dyeing methods.

Color brightness: For products that need to show bright colors, it is recommended to use methods with better dyeing effects, such as vacuum high-temperature dyeing. This method can ensure that the dye fully penetrates into the fabric and presents a uniform and bright color.

Color fastness: Color fastness is one of the important indicators for evaluating the quality of dyed fabrics. For products that need to withstand frequent washing or friction, it is crucial to choose a dyeing method that can improve color fastness, such as using a fixing agent or a special dyeing process.

Environmental protection requirements: With the increase in environmental awareness, more and more consumers and companies have begun to pay attention to environmental issues in the dyeing process. When choosing a dyeing method, its impact on the environment, including wastewater discharge and energy consumption, needs to be considered. Therefore, environmentally friendly dyes and energy-saving dyeing equipment are preferred to reduce the negative impact on the environment.