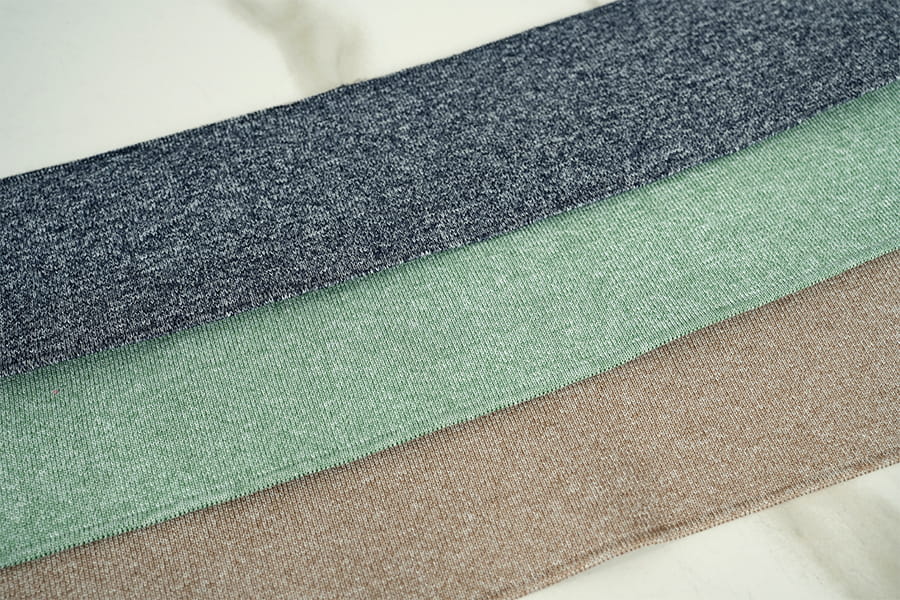

Hem rib is a fabric structure widely used in clothing design, especially in the hem of sportswear, casual wear and underwear. It is favored by designers for its unique elasticity and visual beauty.

Basic concept of hem rib

Hem rib is generally made of two or more fibers (such as polyester and elastic fiber) interwoven to form a fabric structure with elasticity and shrinkage. This structure not only effectively maintains the shape of the clothing, but also provides excellent wearing comfort. The weaving process of hem rib mainly includes knitting and weaving, each with its own characteristics to meet different design needs.

Knitting process

Knitting is one of the most commonly used weaving processes for hem rib. It is interwoven through a series of continuous coils and has good elasticity and breathability. Knitting processes can be divided into many types, mainly including:

Plain knit: As the most basic form of knitting, plain knitting is suitable for making simple rib structures. Its characteristics are the softness and comfort of the fabric, which is particularly suitable for the needs of underwear.

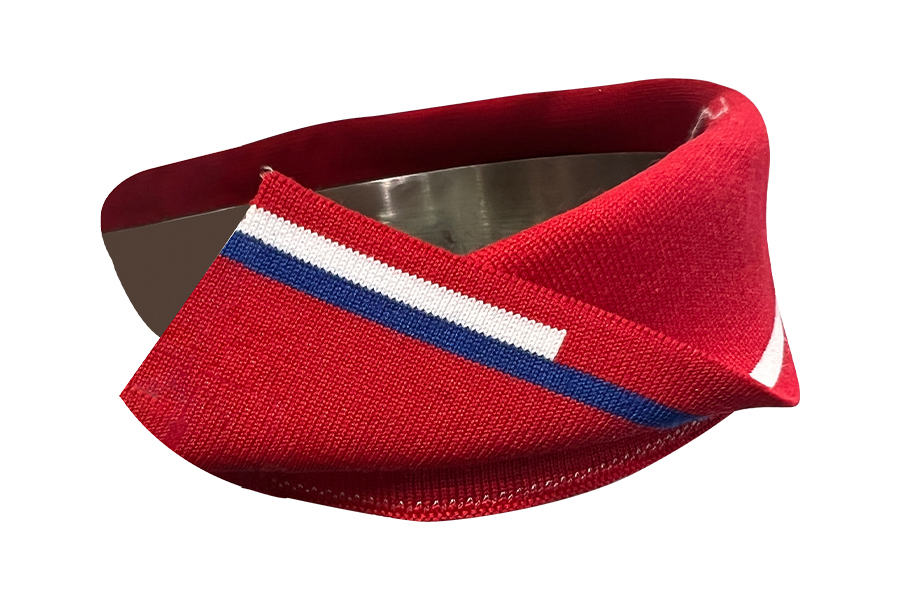

Rib Knit: Rib knit is a process designed specifically for hem ribbing, usually with alternating plain and purl stitches. By changing the stitches, different ribbing effects can be achieved, such as 1x1, 2x2, etc. This structure not only enhances the elasticity of the fabric, but also ensures that the hem fits the body better and effectively prevents the clothes from slipping off.

Circular Knit: Circular knitting is a continuous knitting process suitable for mass production, which can quickly produce large-format fabrics and is widely used in the hem part of sportswear and casual wear.

Weaving process

Although knitting is the main weaving method for hem ribbing, weaving is also used in specific cases. Woven fabrics are woven by interlacing warp and weft yarns, and usually have high strength and wear resistance. In the weaving process, the hem ribbing mainly adopts the following technologies:

Plain Weave: Plain weave is the simplest form of weaving, suitable for making hem ribbing with simple structure. Although its elasticity is not as good as knitting, its elastic properties can be enhanced by adding elastic fibers.

Twill Weave: Twill weave shows a clear twill effect and is suitable for making more complex hem designs. Its advantages lie in the strength and wear resistance of the fabric, which is particularly suitable for the needs of high-intensity sportswear.

Satin Weave: Satin weave can produce a smooth surface and is suitable for making the hem part of high-end clothing. Although satin fabrics have poor elasticity, their performance can be effectively improved through blending technology.

Application Fields and Prospects

Hem ribbing not only occupies an important position in the fashion industry, but its application in functional clothing is also increasingly valued. With the continuous improvement of consumers' demand for comfort and functionality, the diversified development prospects of hem ribbing are broad. Designers can flexibly choose suitable weaving processes according to different market needs to achieve the best wearing experience and visual effects.