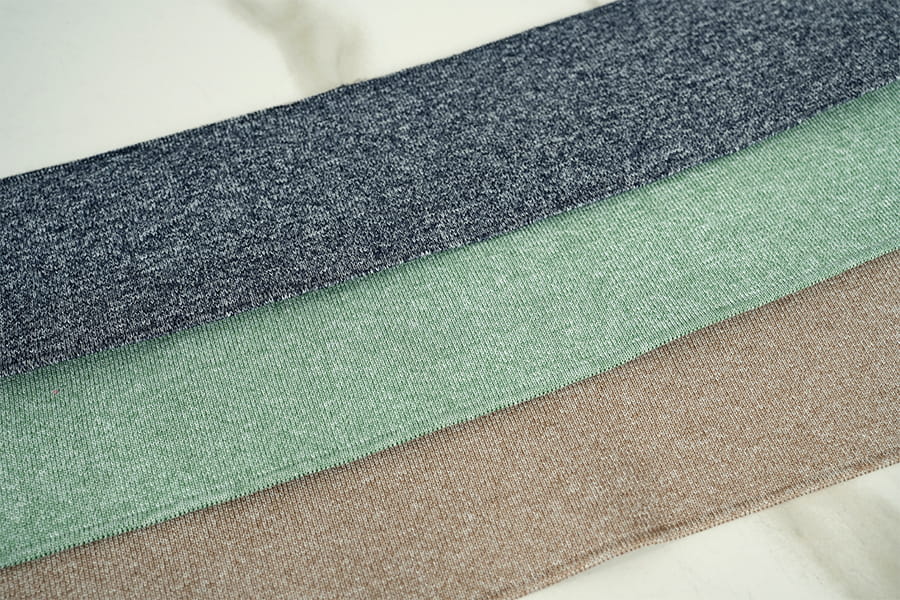

As a fabric that combines comfort and elasticity, Cotton Spandex Collar Rib occupies an important position in the textile industry due to its unique fiber composition and structure. Its application range covers a variety of clothing such as sportswear, casual wear and underwear. However, there are many factors that affect its dyeing performance, which is not only related to the appearance of the fabric, but also directly affects the quality and market competitiveness of the product.

Influence of fiber composition and structure

Cotton Spandex Collar Rib is composed of a blend of cotton fiber and spandex fiber. The physical properties of these two fibers and their ratio play a key role in the dyeing process.

Cotton fiber: As a natural fiber, cotton fiber is favored for its superior moisture absorption and breathability, and its dyeing performance is good. However, the surface of cotton fiber is relatively rough and may contain natural impurities, which may affect the uniform adsorption and penetration of dyes.

Spandex fiber: Spandex is known for its excellent elasticity, but it is relatively weak in dyeing. Spandex has a smooth surface and has a strong affinity for weak polar dyes, but a poor affinity for strong polar dyes. In addition, spandex is prone to thermal expansion and contraction at high temperatures, which may cause changes in the fiber structure during the dyeing process, thereby affecting the final dyeing effect.

Dye Selection and Performance

Dye selection is another important factor affecting the dyeing effect of Cotton Spandex Collar Rib.

Dye Type: Different dyes have significant differences in affinity for cotton and spandex fibers. Reactive dyes usually have a higher affinity for cotton fibers, while disperse dyes are more suitable for spandex fibers. Therefore, the selection of dyes needs to fully consider the characteristics of the fiber and the specific dyeing needs.

Dye Stability: The stability of the dye is directly related to the durability of the dyeing effect. Some dyes are prone to decomposition or fading under high temperature, light or chemical action, which in turn affects the color fastness and appearance of the fabric.

Dye Particle Size: The size of the dye particle size also has a significant effect on the dyeing effect. Dyes with smaller particle size are easier to penetrate into the fiber to achieve uniform dyeing, but too small particle size may cause dye agglomeration and precipitation, which in turn affects the dyeing effect.

Optimization of Dyeing Process Parameters

The selection and adjustment of dyeing process parameters are crucial to the dyeing performance of Cotton Spandex Collar Rib.

Dyeing temperature: Dyeing temperature is an important factor affecting dye diffusion and fiber structure changes. Appropriate dyeing temperature can accelerate dye diffusion and adsorption and improve dyeing efficiency. However, too high a temperature may cause fiber damage and dye decomposition, affecting the final effect.

Dyeing time: The length of dyeing time directly affects the penetration and fixation of the dye. Too short a dyeing time may cause the dye to fail to fully penetrate the fiber, while too long a dyeing time may cause excessive penetration of the dye and even damage the fiber.

pH value control: Changes in pH have an important impact on the stability of the dye and the fiber structure. During the dyeing process, the pH value must be strictly controlled within an appropriate range to ensure the ideal dyeing effect and the integrity of the fabric.